If you’re in the process of restoring a classic car, one important task that can’t be overlooked is rust removal. Rust can ruin a vehicle’s appearance and cause further damage to its body if not addressed properly.

Fortunately, there are several options available for those looking to remove rust from their cars – but which option is best? In this article, we’ll explore some of the most popular methods for removing rust from vehicles and discuss what benefits each one offers. We’ll also cover tips on how to ensure your car restoration project goes as smoothly as possible.

So get ready to learn all about rust removal and find out which solution would be right for you!

Common Methods of Rust Removal

When it comes to rust removal for car restoration, there are several effective methods available. One popular method is wire brushing, which involves using a stiff brush with metal bristles to manually remove the rust from the affected area.

This can be time-consuming but very effective when done properly. Sandblasting is another option that uses compressed air and abrasive particles such as sand or glass beads to blast away the rust.

Chemical agents are also an option; these contain active ingredients like phosphoric acid that will dissolve the rust without damaging other parts of your car. There are also specialty solutions on the market specifically designed for removing rust from cars without causing any damage.

Lastly, you could opt for electrolytic treatments where electricity is used to remove corrosion from metal surfaces quickly and efficiently. Whichever method you choose, make sure it’s suitable for your specific project so you get optimal results!

Pros and Cons of Different Rust Removal Techniques

When it comes to removing rust from cars, there are several different techniques available. Each method has its unique advantages and disadvantages that should be taken into consideration when making your decision.

For example, sandblasting is fast and can strip away old paint layers while also removing minor surface rust stains in one pass; however, this technique requires specialized equipment or professional assistance for larger jobs which can be costly. On the other hand, chemical treatments have the advantage of being more affordable with less labor involved but may take longer as they must remain on the surface during their reaction period before being removed and rinsed off afterward.

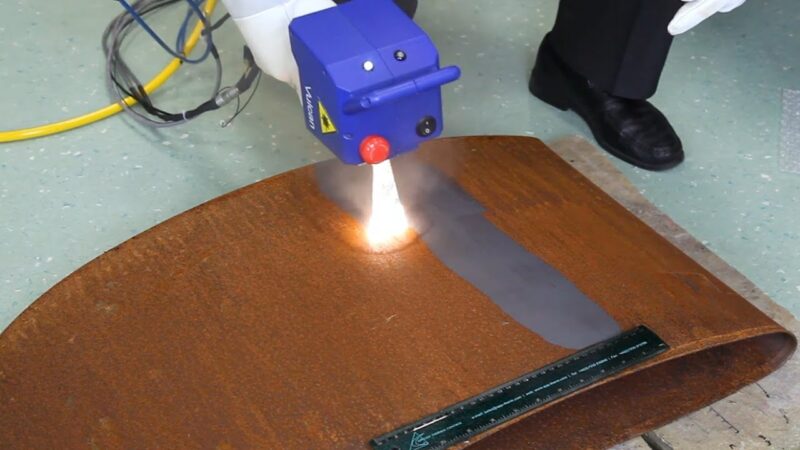

Additionally, certain chemicals used in these processes could pose environmental risks if not handled properly. Mechanical tools like wire brushes or grinding discs offer another solution which is effective but labor intensive when it comes to large areas with heavy corrosion build-up while laser rust removal machines provide a third alternative that is quick and accurate without creating hazardous dust particles or pollutants like some other methods do – perfect for car restoration projects where precision matters most!

Tips for Choosing the Right Technique for Your Project

When it comes to choosing the right rust removal technique for your car restoration project, there are a few key tips to keep in mind. Start by researching each potential option so you can make an informed decision based on what would work best for your specific needs.

Consider factors such as cost, ease of use, and time commitment associated with each process before making a choice. Additionally, it’s important to identify both the type of rust on your vehicle and its location to select an appropriate method.

Lastly, be sure to have all of the necessary safety gear on hand before beginning any rust removal process – this could include masks or goggles if working with abrasive materials or protective gloves when handling certain chemical solutions that may pose risks if not handled properly. Following these steps will help ensure optimal results while also helping you stay safe during your project!