Linear actuators are present in many applications driving today’s technology. One fact is, without their control systems, these motion devices won’t work. At least, they won’t work as well as they currently do.

The control system is critical for many reasons. And it’s of different types with diverse components. As a result, they also have varying applications. We’ll cover all about their types, components, and applications in this post.

Table of Contents

Components of A Linear Actuator Control System

A typical linear actuator control system will feature the following components:

Power source

The power source is a primary component of any linear actuator control system. It delivers the energy the device uses. And can be electrical, mechanical, hydraulic, or pneumatic. In a typical setting, the power source will transfer energy to and from the actuator.

Electric power sources are more common and can be AC or DC. AC powered actuators are best for high-precision applications and DC for low-voltage ones.

Controller

From its name, it’s evident that the controller component is an integral part of the control system. As you use your linear actuator, you’ll need to adjust certain settings. These include speed, position, and direction, among others. And the controller is the component responsible for that.

In simple words, controllers determine the actuator’s movement. How? They interpret input and feedback signals, depending on the application requirements. Then, they adjust the device’s movements to fit the application. Generally, you’ll have to settle for a digital or analog controller.

Feedback

Linear actuator control systems track the device’s operations. That’s how they adjust components to improve performance. For this reason, the feedback component is critical. It tells the control system if the actuator is performing well or not.

As its name says, it provides feedback to the actuator following user input and other sensor data. In particular, the component sends real-time details on the position of the device. The control system then uses this info for accurate performance.

Interface

Another vital component is the interface. It’s the component you interact with when customizing the linear actuator. So, it acts as a middleman between you and the control system.

The interface will feature elements like switches, buttons, and knobs. But that’s for physical types. Wireless options use remote controls and apps on smartphones, tablets, and computers.

Types of Linear Actuator Control Systems

Linear actuator control system types influence their applications. Below are the most common ones:

Open-loop

Open-loop linear actuator control systems lack a feedback component. In other words, they don’t follow the position or motion of the device in real-time. But this doesn’t mean they are unsafe. Rather than auto-adjusting components, open-loop systems leave the task to the user. So, the linear actuator will only work according to your input.

Closed-loop

Closed-loop control systems are the inverse of the open-loop ones. They come with the feedback component and rely on it to optimize performance. Hence, closed-loop control systems auto adjusts components as conditions change and errors occur.

Analog

When talking about analog systems, the discussion is always about continuous signals. So, analog control systems use continuous signals to control motion. Such types will feature more non-digital components. As a fact, the controller and feedback parts will be analog.

Digital

With a digital control system, the linear actuator operates using discrete signals. Discrete signals, in this case, consist of just two values: 0 and 1. Like analogs, this control system type will feature native components.

You’ll expect a digital controller, feedback device, and driver, among others. Digital tech is contemporary. Hence, most modern linear actuator applications require a digital control system.

Manual

Another common type of linear actuator control system is the manual. As you’d expect, these are control systems you operate by hand. They feature buttons and switches, and levers. You’ll mostly find manual linear actuator control systems in mechanical linear actuators. It makes sense considering mechanical devices usually lack automation.

Automatic

If you get a flexible linear actuator, it will likely have an automatic control system. This control system type makes regulation a lot easier as they’re programmable. The majority of them are also wireless, ensuring contactless control.

You can learn more about the linear actuator control system types on this website.

Linear Actuator Control Systems Applications

We’ve talked about the components and types of linear actuator control systems. Now, let’s consider their applications:

Industrial automation

Industrial machines rely on linear actuator control systems for accurate movements. In particular, analog control systems are more common in this application. Consider machines that use fluids and gases. Such tools will have valves or dampers, which work best with continuous signals.

Medical equipment

In hospitals and clinics, beds, chairs, tables, and scanners all undergo movements. Hence, they need linear actuators and their control systems. Automatic and digital linear actuators are common with medical equipment. Electric-powered linear actuators are the norm in this application. As a result, the control system cannot be manual or analog.

Home automation

When it comes to home automation, different linear actuator control systems are workable. But the most common is the automatic type. Home automation systems are usually programmable. Thus, they use wireless automation with remotes and apps. An automated linear actuator control system allows these.

Manual control systems are applicable in home automation, too. Instances are linear actuators installed to open a window or door at the press of a button. Furthermore, you can also expect open-loop control systems in devices with timers. Once you set the time, the control system won’t adjust it based on any feedback.

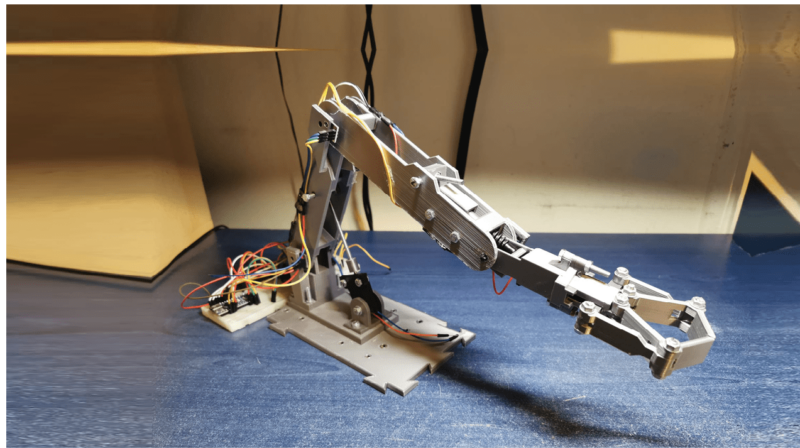

Robotics

In robotic applications, digital and closed-loop linear actuator control systems are prevalent. Consider a robotic arm that operates via a predefined trajectory. It’s a dynamic movement that changes at any time. As a result, it’s only possible if the control system is digital. That way, the controller can adjust performance according to real-time input.

Conclusion

Linear actuators need control systems to balance their performance. Without them, the motion devices won’t work at their best. The control systems have several parts and are of different types.

As explained, linear actuator control systems have many use cases. Understanding how they work will help you get a device with a suitable control system for your application. You can count on the information in this post as a guide.