In the ever-evolving world of automotive engineering, laser-cutting machines are revolutionizing car design and pushing the boundaries of what’s possible. From customizing exterior features to developing intricate interior designs, these powerful tools are enabling designers to create cars that look like works of art while offering unparalleled performance.

With its precise cuts and wide range of materials available for use, laser cutting technology is quickly becoming an invaluable asset in the auto industry. This article will explore how this cutting-edge technology is transforming car design and uncovering new possibilities for engineers in the process.

Table of Contents

Unleashing the Power of Laser Cutting Machines in Automotive Design

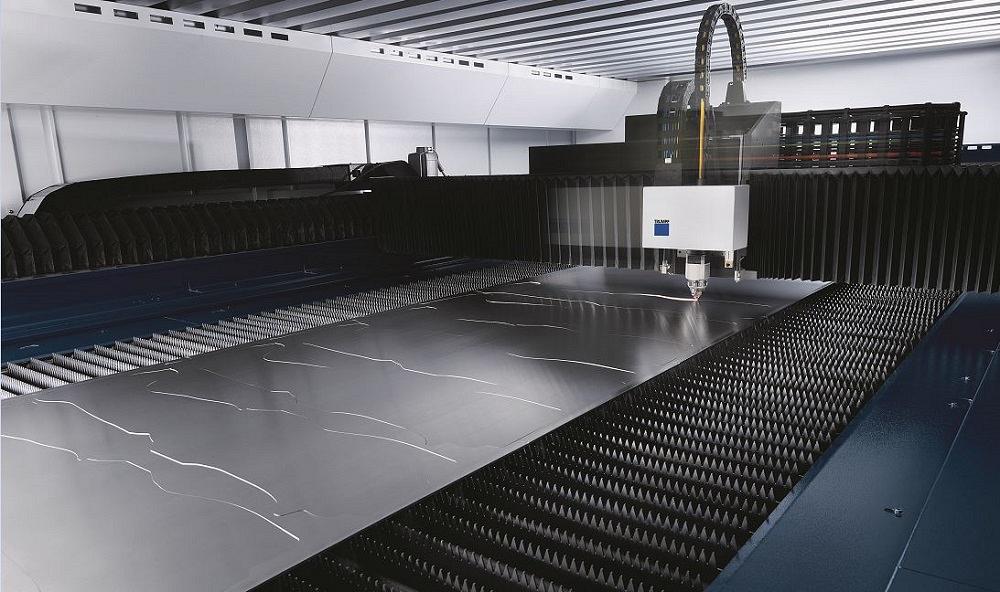

The automotive industry is rapidly evolving and improving, and laser-cutting machines are playing a major role in the revolution. With their precision-based design and superior accuracy, laser-cutting machines can help create car designs that were once thought to be impossible.

Laser cutters offer tremendous flexibility when it comes to creating intricate shapes with incredible detail. This makes them ideal for making highly complex parts such as door handles, grilles, roof channels, body panels, control arms, and more.

The use of lasers also enables manufacturers to reduce costs while producing higher-quality products faster than ever before. In addition to cost savings and improved production times, laser-cutting technology offers greater levels of efficiency by eliminating most secondary finishing operations like grinding or polishing.

The ability to quickly program new parts reduces the development time significantly which increases productivity even further. Moreover, using lasers for prototyping allows engineers to explore different ideas without having any limitations on material choice or complexity levels during the development process – something that could not be achieved using traditional methods alone.

The benefits of utilizing laser cutters are undeniable: they provide increased speed and accuracy while reducing overall costs; they enable designers to be creative with no restrictions; they allow rapid prototyping for real-time testing; lastly but importantly – they ensure high-quality results every time! By unleashing the power of these versatile tools within automotive engineering processes carmakers have been able to bring revolutionary designs from the concept stage into reality quicker than ever before – all thanks to laser-cutting machines!

Redefining Car Design with Advanced Lasers

Laser-cutting machines are revolutionizing automotive engineering by redefining the possibilities of car design. For decades, cars have been designed using traditional manufacturing methods, but with advanced lasers now available, designers and engineers can create more intricate and innovative designs than ever before.

Not only do laser-cut components allow for greater levels of detail and precision in car design, but they also reduce production costs significantly compared to other manufacturing techniques. This makes it possible to develop new shapes for vehicles that were impossible to manufacture previously due to their complexity or cost barrier.

The potential applications for laser cutting technology in car design are seemingly endless – from customizing bodywork styles to creating efficient air ducts that optimize airflow around the vehicle. In addition, laser cooling systems can be used on high-performance engines so they remain at an optimal temperature while running at full power for extended periods without overheating. The combination of these technologies allows automotive engineers to create cars that perform better than ever before while still maintaining a stylish shape tailored specifically to each customer’s needs and desires.

As a result of this newfound freedom in designing cars enabled by advanced lasers, entire industries are being disrupted as automakers rush toward the forefront of innovation in this field. With faster production times and cheaper costs associated with utilizing laser-cut parts over traditional methods, the future looks bright when it comes to developing unique vehicles tailored perfectly to any driver’s wants or needs – all thanks to cutting-edge laser technology!

Exploring the Possibilities of Laser-Cut Cars

The possibilities of laser-cut cars are limitless. By using this technology, car designers can create intricate shapes and designs that would’ve been impossible to achieve previously.

From frame modifications to unique exterior finishes, laser-cutting machines can revolutionize automotive engineering in ways never before imagined. Not only does laser cutting provide a precision-based method for creating complex designs but it also allows for faster production rates than traditional methods.

Furthermore, with its capacity for customizing parts on demand, laser cutting is becoming increasingly popular among car manufacturers who want to offer customers a personalized experience when they buy their vehicles. Laser-cut cars enable engineers and designers alike to explore new ideas and avenues of creativity without sacrificing quality or safety standards – allowing them to push the boundaries of what was once thought possible.

Conclusion

The use of laser-cutting machines is revolutionizing the automotive engineering industry. By using powerful and precise lasers, designers can create incredibly intricate car designs that weren’t possible before.

Thunder Laser cutter is at the forefront of this technology, allowing manufacturers to produce custom parts quickly and accurately. With a wide range of materials available, laser cutters are becoming an essential tool for creating modern cars with cutting-edge design features.

Using advanced laser technology, carmakers can now make faster iterations and more reliable vehicles in fewer steps than ever before.